14 Feb Fit for the grind: NTN’s Mill trunnion bearings

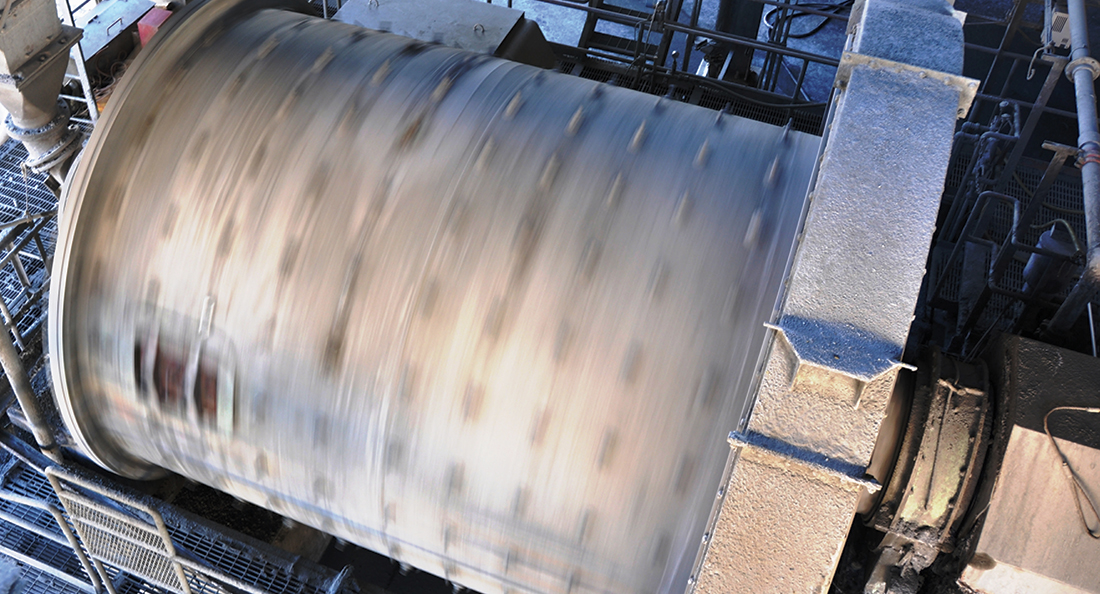

When the bore diameter of a bearing is 1.5 metres, it’s not classified as an ‘off-the-shelf’ item. Yet these extra-large bearings are often employed on critical pieces of equipment, such as the trunnions of grinding mills at mine sites. This is why a trusted supplier with engineering expertise in the installation and maintenance of these bearings is so important to the customers that use them.

“These trunnion bearings are selected based on the grinding mill size and type, in addition to the site conditions and output required of the mill,” says Fabio Rebecchi, Product Manager for NTN-CBC Australia. “In these instances, we’re seeing a trend for extra-large spherical roller bearings, which are critical in ball mill application. The end users will keep a spare on site and have them constantly monitored to avoid downtime.”

Engineering Manager for CBC, Anthony O’Keefe, has experience supplying these to mining customers in Australia. Because of the arduous nature of the ball mill application and the time it takes to manufacture these colossal bearings, O’Keefe says having a reliable supplier is essential.

“We’ve got extensive supply availability through our manufacturers, such as NTN, so we can help provide customers with both the product and technical support,” he explains. “These are not ‘readily available’ bearings and so the customers that use them need to know they can access them if they need to. CBC’s position of strength is the availability of stock that we have for our customers – we’ve got over $80 million worth of stock in our branches and warehouses across Australia – and the engineering support we can provide on the back of these very large bearings is simply peerless.”

According to Rebecchi, extra-large spherical roller bearings are primarily used in these applications as they are easier to maintain and have an extremely high load-carrying capacity. Recently, in combination with CBC, NTN had an order to supply a North Australian mining operation with trunnion bearings.

“In relation to these trunnion bearings and mill bearings, NTN have had a long history in supplying these to the Australian marketplace – actually since the late 1970s. NTN always have a number of these bearings in various stages of production and delivery,” adds Rebecchi.

What is unique about the Australian offering is that the Japanese manufacturer NTN and CBC have a long-standing joint venture company – NTN-CBC (Inenco) – and one of the directors of this joint venture, Mr Jerry (Takao) Maki, is based locally.

This business arrangement – and Maki’s presence in Australia – bodes well for customers in the mining sector. Maki has held various posts with NTN across the globe. He has been with the company since 1981 and worked in eight different countries outside of Japan. His ability to tap into the NTN global network and directly communicate with the company’s manufacturing division is a key benefit for customers.

“Bearings are highly engineered products, particularly trunnion bearings which can weigh over two tonnes and take several months to make. So being that bridge to Japan where we can provide feedback about specific customer requirements is a big benefit. We have total access to the manufacturing division,” explains Jerry. “It’s all about uptime of machinery with the customer, and us providing superior products. We can provide that through several different avenues, whether that is in material enhancements or design enhancements in Japan.”

Moreover, the close relationship that CBC has with customers brings additional opportunities with the NTN-CBC joint venture.

“CBC have traditionally been very strong in the mining industry, providing complete package programs for customers that not only include bearings, but bearing componentry and power transmission,” Rebecchi says. “In conjunction with our unique access to the NTN manufacturing division, we’re able to come up with very tailored solutions to particular applications. And our close relationship with customers allows us to give a direct contact to the plant and therefore shorten that lead time process from conception, design and delivery.”