20 Jun Enhance Efficiency with Gates® Predator™ V-Belts

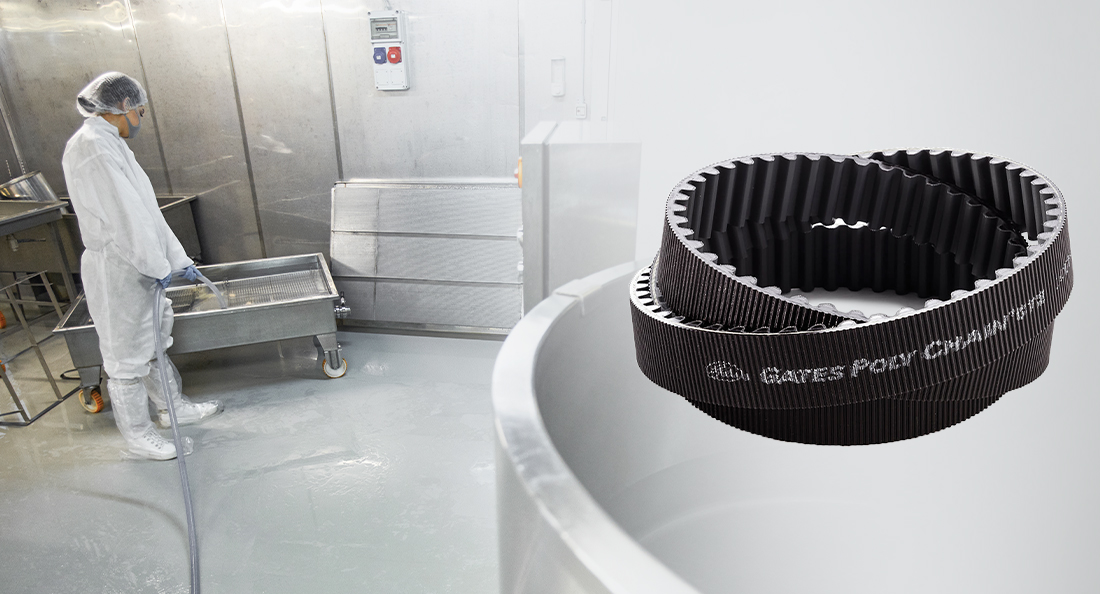

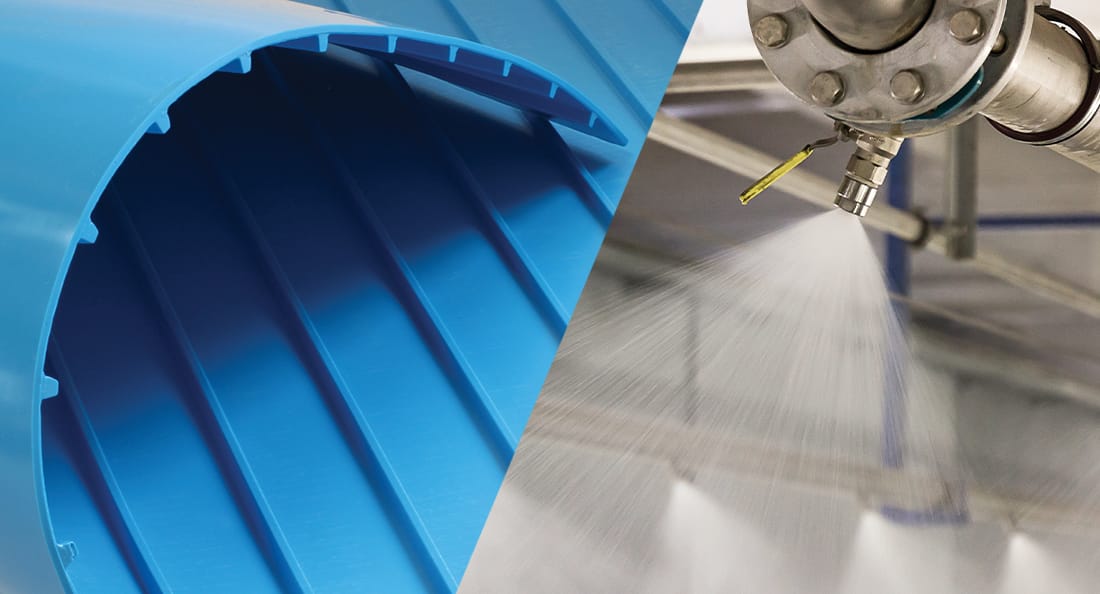

"By utilising Gates® Predator™ v-belts, you can reduce the number of belts in your drive system by up to half," highlights Rob Michelson, an expert in Power Transmission at Motion. "Furthermore, the unique design of the Predator belt enhances equipment longevity." The importance of v-belts in the...