22 Feb Gaining the benefits of high-efficiency motors

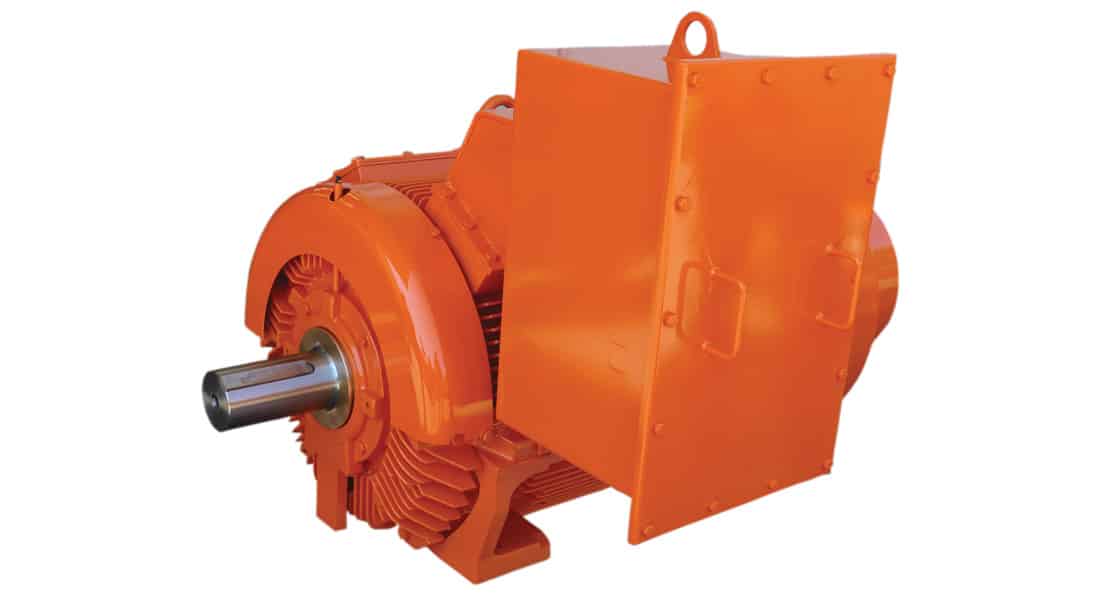

With electric motors responsible for over 80% of electricity use in heavy industries, it’s a sensible choice for mines to adopt energy-efficient motors of IE3 efficiency level and above. Through TECO Australia, CBC provides a range of high-efficiency motors to the mining industry – including the TECO...